When Your Home’s Air Circulation Stops Working

Heater fan motor replacement becomes necessary when your home’s heating and cooling system stops circulating air properly. Here’s what you need to know:

Key Signs You Need Replacement:

- No air coming from vents

- Weak airflow throughout your home

- Strange noises (squealing, banging, rattling)

- Burning smell from vents

- System runs but doesn’t heat or cool effectively

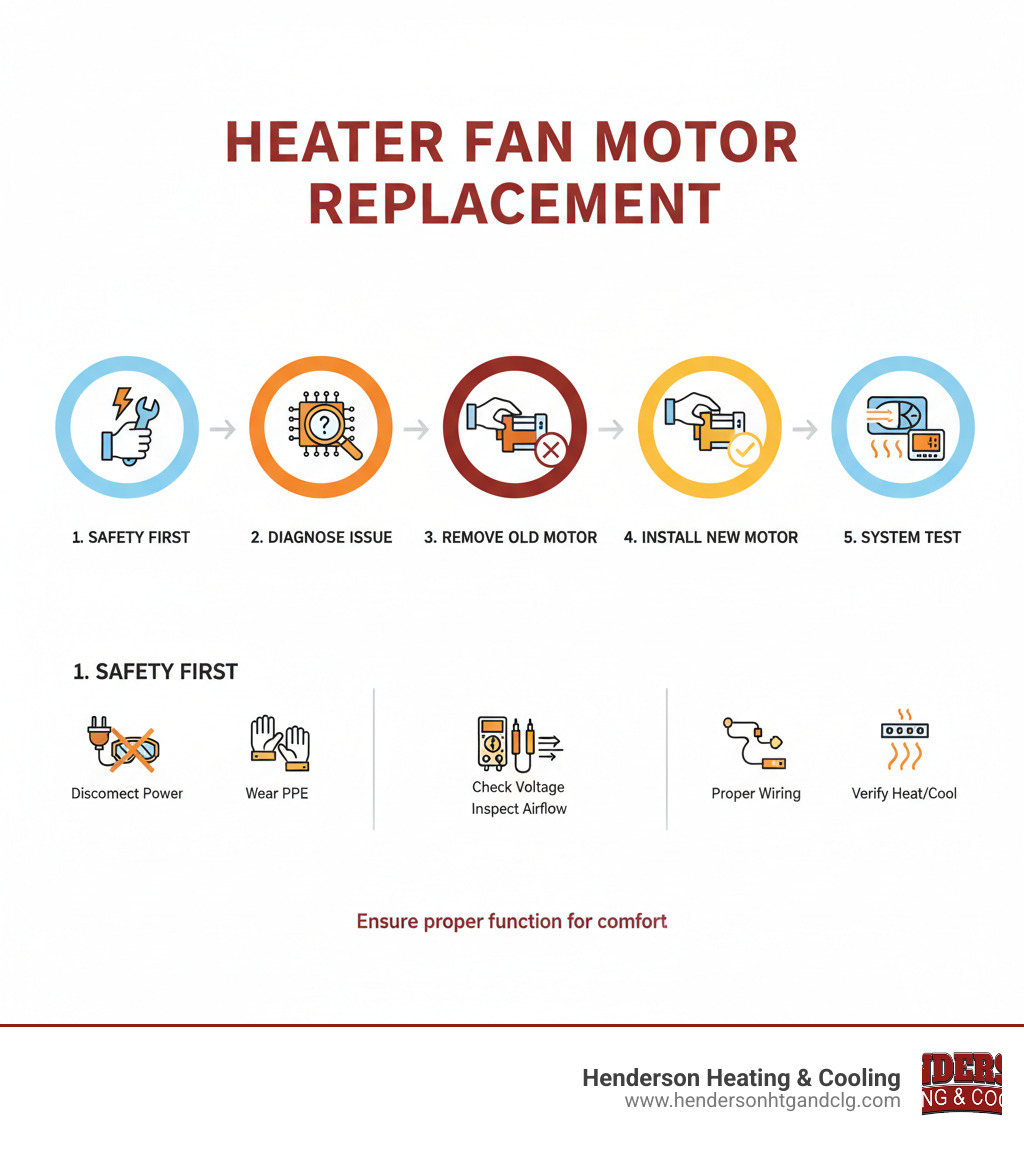

Typical Replacement Process:

- Professional diagnosis – Testing electrical components and airflow

- Safe removal – Disconnecting power and removing old motor

- Installation – Installing new motor with proper wiring

- Testing – Verifying proper operation and airflow

The blower motor is the heart of your HVAC system. It’s the component that moves conditioned air through your ductwork and into every room of your home. When it fails, your entire heating and cooling system stops working effectively, even if the furnace or air conditioner itself is running perfectly.

Without a functioning blower motor, you might hear your system turn on, but you won’t feel any air coming from your vents.

Most blower motor failures happen gradually. You might notice weaker airflow first, followed by unusual sounds, before the motor stops working completely. Restricted airflow from dirty filters is the leading cause of blower motor failure, as it forces the motor to work harder than designed.

The Heart of Your HVAC: Understanding the Heater Fan Motor

Think of your HVAC system’s blower motor as the heart that keeps your home’s air flowing. Without it, even the best furnace or air conditioner in the world would be like having a car with no wheels – technically functional, but unable to deliver what you need.

This hardworking component lives inside your air handler or furnace, quietly doing one of the most important jobs in your home. The blower motor pulls air from your return ducts, pushes it past your heating or cooling coils, and then sends that perfectly conditioned air through your supply ducts to every room.

Whether you’re cranking up the heat on a chilly Missouri morning or cooling down after a hot summer day, your blower motor is the unsung hero making it all happen. It’s what transforms your furnace’s heat or your air conditioner’s cooling into the comfortable air that actually reaches you.

When homeowners need heater fan motor replacement, they’re usually dealing with this essential component that works year-round to keep their families comfortable.

For a deeper dive into how all these components work together, check out our HVAC terminology guide.

AC Blower Motor vs. Furnace Blower Motor

Here’s something that surprises many homeowners: there’s actually no difference between your “AC blower motor” and your “furnace blower motor.” They’re the same component!

This single motor handles both jobs throughout the year. In winter, it circulates warm air from your furnace. In summer, it moves cool air from your air conditioning system. It’s like having one reliable employee who can handle two different departments.

This shared component design makes your HVAC system more efficient and simpler to maintain. When this motor needs replacement, you’re fixing the air circulation for both your heating and cooling needs at once.

How Blower Motor Technology is Changing

The world of blower motors has gotten pretty exciting lately – and yes, we know that sounds funny coming from HVAC folks! But seriously, the technology improvements are making a real difference for homeowners.

The old-school motors were called Permanent Split Capacitor (PSC) motors. These were simple and reliable, but they had one speed: full throttle. Imagine if your car could only go 60 mph whether you were in a school zone or on the highway – that’s basically how these motors worked.

New federal efficiency standards called Fan Energy Rating (FER) requirements are phasing out these less efficient motors. The government realized that better motor technology could save homeowners money and help the environment.

Today’s smart motors are like having a computer controlling your airflow. Electronically Commutated Motors (ECM) constantly monitor airflow through RPMs and electrical draw, adjusting their speed to give you exactly what you need. No more, no less.

Constant Torque Motors (CTM) – including popular brands like X13 – take a different approach. They calculate torque and electrical draw to maintain steady airflow even when conditions change in your ductwork.

These newer motors are fantastic for your energy bills and provide quieter, more consistent comfort. They start up gradually instead of jolting to life, which means less wear and tear over time.

The trade-off? Modern motors are more sophisticated and typically require exact replacements rather than universal parts. When you need a replacement, it often needs to be the specific motor designed for your system.

You can learn more about the differences between variable speed and X13 motors and the federal efficiency standards driving these improvements.

Telltale Signs Your Blower Motor is Failing

When your home’s heating or cooling system starts acting up, the blower motor is often the culprit. Here’s the thing though – it rarely just dies overnight. Most of the time, your blower motor will give you plenty of warning signs that it’s struggling. Learning to recognize these early signals can save you from those uncomfortable nights when your system completely gives up.

The most obvious sign something’s wrong is weak or no airflow from your vents. You’ll hear your furnace or AC kick on like usual, but when you walk over to check the vents, there’s barely a whisper of air coming out. Sometimes you might feel a little airflow, but it’s noticeably weaker than what you’re used to. This is your blower motor telling you it’s having trouble doing its job.

Strange noises are another dead giveaway that your motor is in distress. Your HVAC system should hum along quietly in the background. When you start hearing new sounds, it’s time to pay attention. A squealing or chirping noise usually means the motor’s bearings are worn out and crying for help. Grinding or scraping sounds are more serious – they often indicate severely damaged bearings or the fan wheel scraping against its housing. Banging or rattling might mean something’s come loose or debris has found its way into the blower assembly. For more details on what these noises mean, check out our guide on Common Causes of Noisy HVAC Systems.

If your system keeps shutting off before reaching the temperature you’ve set on your thermostat, you might have an overheating blower motor on your hands. When motors struggle, they work harder, get hotter, and trigger the safety switches that protect your system from damage.

A burning smell from your vents should never be ignored. Sometimes it’s just dust burning off after the system hasn’t run for a while, but it could also signal electrical insulation burning due to a motor short or severe overheating. Either way, it’s worth having a professional take a look immediately.

Don’t overlook unusually high energy bills either. A failing blower motor has to work overtime to move air through your system, and all that extra effort shows up on your electric bill. If your usage habits haven’t changed but your bills have spiked, your blower motor might be the reason.

Common Causes of Blower Motor Failure

After years of servicing HVAC systems throughout Southwest Missouri, we’ve noticed some patterns in what causes blower motors to fail. Understanding these can help you avoid a heater fan motor replacement down the road.

Restricted airflow is by far the biggest killer of blower motors. When your motor can’t move air freely, it’s like asking someone to run a marathon while breathing through a straw – eventually, they’re going to collapse from exhaustion.

The number one culprit? Dirty air filters. We can’t say this enough – a clogged filter is your blower motor’s worst enemy. It blocks airflow, forces your motor to work harder, creates high static pressure in your ducts, and eventually leads to overheating and failure. It’s such a simple thing to prevent, yet we see it cause expensive repairs all the time.

Blocked return vents can cause similar problems. That couch you pushed in front of your return vent might seem harmless, but it’s making your blower motor struggle. The same goes for debris that accumulates in your ductwork over time.

Electrical issues are another common cause of failure. Your blower motor depends on steady electricity to do its job. A bad capacitor or relay can prevent the motor from starting or cause it to run erratically. Thermostat problems or issues with your system’s control board can send confusing signals to the motor. And power surges during storms can fry the motor’s delicate internal components instantly.

Sometimes it’s just good old-fashioned wear and tear. Motor bearings wear out over time, especially if they lose lubrication. When bearings fail, you’ll hear grinding noises before the motor seizes up completely. Loose motor mounts can cause vibrations that damage other components. Even the blower wheel (that “hamster cage” looking thing) can develop problems – broken fins or heavy dirt buildup can throw it off balance.

The sad truth is that many of these problems could be caught early or prevented entirely with regular professional maintenance. Skipping tune-ups allows small issues to snowball into expensive repairs.

What About My Car’s Heater Fan Motor?

While we focus on home HVAC systems, your car’s heater fan motor can develop similar problems. The symptoms are pretty much the same – no air from the vents, weak airflow, squealing or rattling noises, or the fan only working on certain speeds.

Cars face some unique challenges though. Leaves and debris can get sucked into the system more easily than in your home. Age and electrical problems are common culprits, and worn bearings cause the same grinding noises you’d hear in a home system.

For older car models, sometimes these motors can be repaired by cleaning and lubricating components. However, for most modern vehicles, replacement is usually the more reliable solution when the motor fails completely.

The Professional Approach to Heater Fan Motor Replacement

When your home’s comfort depends on a failing blower motor, you want the job done right the first time. While YouTube tutorials might make heater fan motor replacement look straightforward, we’ve seen too many DIY attempts that turned a simple motor swap into an expensive system overhaul. That’s why our Henderson Heating & Cooling team takes a methodical, professional approach that prioritizes your safety and your system’s long-term performance.

Think of it this way: you wouldn’t perform surgery on yourself after watching a few online videos. Your HVAC system deserves the same respect. A professional diagnosis ensures we’re fixing the right problem, and proper installation means your new motor will serve you well for years to come.

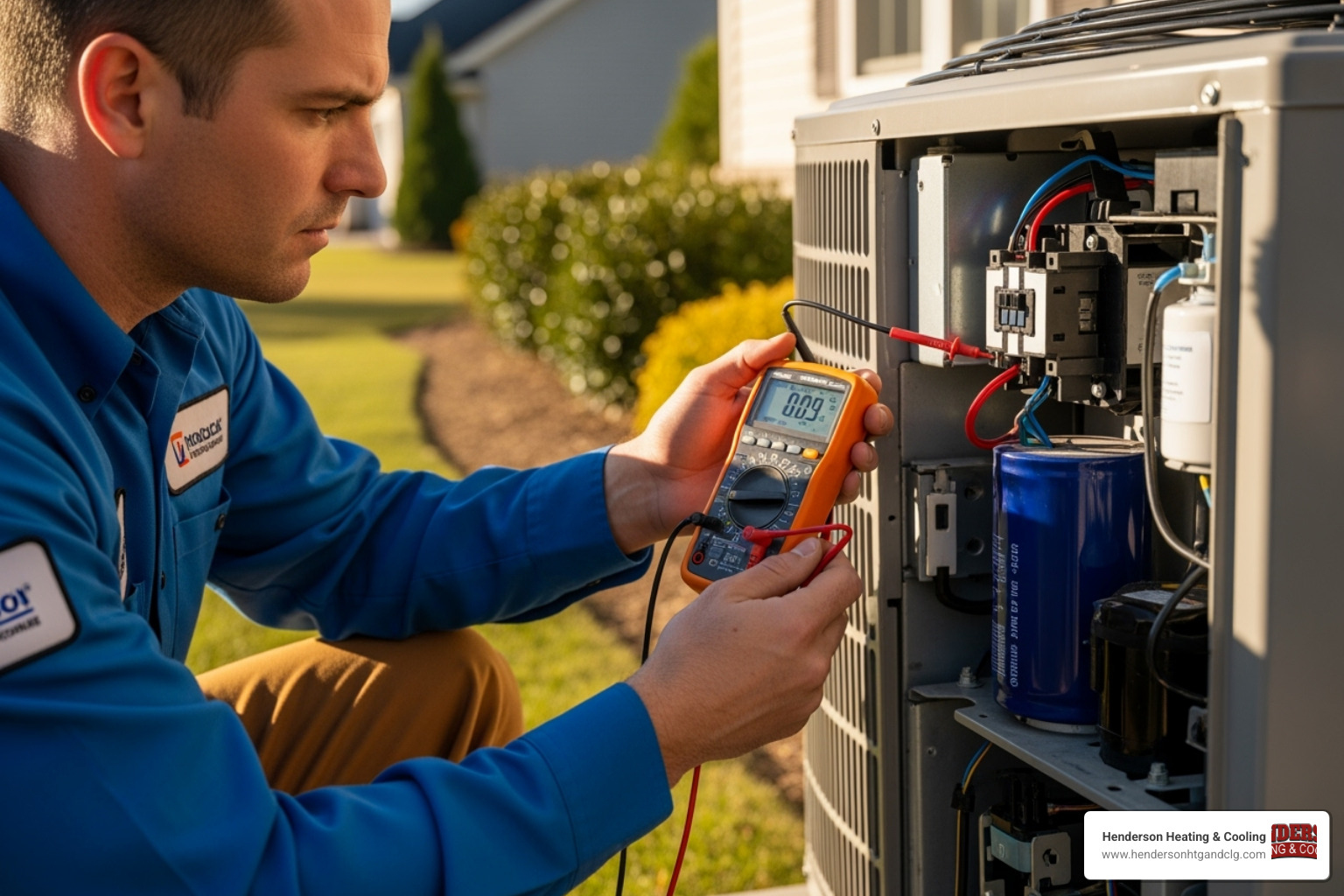

Our technicians start every motor replacement with thorough professional diagnosis. We use specialized tools for electrical testing to verify voltage and amperage levels, ensuring the problem is actually the motor and not something else upstream. Airflow measurement helps us identify any restrictions that might have contributed to the motor failure in the first place.

Most importantly, we follow strict safety protocols throughout the entire process. We always disconnect power at the main breaker, use lockout procedures, and test circuits before touching any components. The typical replacement time frame ranges from 1.5 to 3 hours, depending on your system’s accessibility and the specific motor type.

Why a DIY Heater Fan Motor Replacement is Risky

We get it – there’s something satisfying about fixing things yourself. But when it comes to blower motors, the stakes are higher than you might think. The electrical shock hazard alone should give you pause. HVAC systems operate on 240-volt circuits that can seriously injure or kill someone who doesn’t know what they’re doing.

Modern systems also involve complex wiring that goes far beyond the simple “red wire to red wire” connections of older units. Today’s ECM and CTM motors communicate with sophisticated control boards through multiple wire connections. One wrong move can fry expensive components that cost more than the original motor replacement would have.

There’s also significant system damage risk when inexperienced hands start removing and installing heavy components inside cramped furnace cabinets. We’ve seen cracked heat exchangers, damaged ductwork, and bent fan wheels that resulted from well-intentioned DIY attempts.

Don’t forget about voiding warranties either. Most manufacturers require professional installation to maintain coverage on your equipment. Incorrect part installation is another common issue – with so many motor types available today, choosing the wrong one can leave you with a motor that doesn’t fit or doesn’t communicate properly with your system.

For more insights on why professional service typically beats DIY solutions, check out our detailed guide: Why HVAC Service Beats DIY Solutions.

How a Technician Diagnoses a Failing Blower Motor

When our Southwest Missouri technicians arrive at your home, we don’t just assume the motor needs replacement because it’s not working. We start with a comprehensive visual inspection, looking for obvious signs like burnt wiring, broken fan blades, or excessive dust buildup that might indicate other underlying problems.

Testing capacitors is crucial, especially on older PSC motors. A bad capacitor can make a perfectly good motor appear dead, so we use specialized meters to check the microfarad ratings against manufacturer specifications. This simple test can save you hundreds of dollars if the capacitor is the real culprit.

Checking voltage tells us whether the motor is receiving proper power, while amperage readings reveal if the motor is drawing too much current – often a sign of mechanical binding or electrical problems within the motor itself. We also spend time verifying thermostat signals to ensure your home’s control system is sending the right commands to the blower.

One step that separates professional diagnosis from guesswork is ruling out control board failure. Modern HVAC systems rely on sophisticated circuit boards that can fail and mimic motor problems. We test these boards to make sure we’re not replacing a good motor when the real problem lies in the system’s brain.

This thorough diagnostic approach ensures that when we recommend heater fan motor replacement, it’s truly the solution your system needs. No guesswork, no unnecessary parts – just the right fix for your specific situation.

Extending the Life of Your Blower Motor and HVAC System

Think of your HVAC system like a car – with regular care and attention, it’ll serve you faithfully for years. But neglect it, and you’ll find yourself facing unexpected breakdowns at the worst possible times. The good news? Extending the life of your blower motor and avoiding premature heater fan motor replacement is easier than you might think.

Regular professional maintenance is like giving your HVAC system an annual physical. When our team visits your Southwest Missouri home for a tune-up, we’re not just checking boxes – we’re looking for the little things that could become big problems. We inspect your blower motor for signs of wear, lubricate accessible bearings, check electrical connections, and make sure everything is running within manufacturer specifications. It’s amazing how many major breakdowns we prevent with these routine visits.

But here’s the thing – you don’t have to wait for our annual visit to take care of your system. The importance of clean air filters cannot be overstated. If we had to pick just one thing that homeowners could do to protect their blower motor, this would be it. A dirty, clogged filter is like asking someone to breathe through a thick blanket – it’s exhausting and unsustainable.

Your air filter should be checked monthly and replaced when it looks dirty. For most homes, this means changing it every 1-3 months, though homes with pets, lots of dust, or family members with allergies might need more frequent changes. When you keep that filter clean, you’re ensuring proper airflow, reducing strain on your blower motor, and keeping your indoor air quality high. It’s a simple task that pays huge dividends.

Balanced ductwork plays a crucial role too, though it’s not something most homeowners think about. When your ductwork is properly designed and sealed, air flows efficiently throughout your home without creating unnecessary resistance. Poorly designed ducts or those with leaks create high static pressure, forcing your blower motor to work overtime. If you’ve noticed that some rooms never seem to get comfortable or your energy bills keep climbing, your ductwork might be the culprit.

All of these maintenance practices work together to prevent premature failure of your blower motor. A well-maintained motor runs more efficiently, uses less energy, and provides more consistent comfort throughout your home. Plus, there’s something satisfying about knowing you’re taking good care of your investment.

The benefits of this proactive approach extend far beyond just your blower motor. Your entire HVAC system will thank you with reliable operation, lower energy bills, and fewer emergency repair calls. For more comprehensive strategies on keeping your system in top shape, check out our guide on regular HVAC repair and maintenance.

Your HVAC system works hard to keep you comfortable year-round. A little attention from you goes a long way in ensuring it can continue doing its job for years to come.

Frequently Asked Questions about Heater Fan Motors

We get a lot of questions from homeowners in Southwest Missouri about their HVAC systems, and blower motors are definitely a hot topic. Let’s tackle some of the most common concerns we hear about heater fan motor replacement and related issues.

Can a failing blower motor be repaired?

This is probably our most frequently asked question, and honestly, the answer isn’t always straightforward. It really depends on what type of motor you have and what exactly went wrong.

If you have an older system with a PSC-type motor, there might be some repair options. Sometimes we can address issues like dry bearings with lubrication, or replace a worn capacitor that helps the motor start up. Think of it like getting a tune-up for an older car – sometimes a little TLC can extend its life.

However, with newer ECM or CTM motors (those fancy computer-driven ones we talked about earlier), repair usually isn’t realistic. These motors are essentially sophisticated computers with moving parts, and when their internal electronics fail, it’s like trying to fix a smartphone with a hammer. Heater fan motor replacement is almost always the way to go with these modern systems.

The type of failure matters too. If it’s an electrical component like a capacitor that’s gone bad, that’s often fixable. But if the motor windings are burnt out or the bearings are completely seized, you’re looking at replacement territory.

Our technicians will always give you an honest assessment. We’ll tell you if a repair makes sense or if replacement is your best bet for long-term reliability.

How long does it take to replace a blower motor?

Good news – you won’t be without heat or air conditioning all day! Most heater fan motor replacement jobs take us about 1.5 to 3 hours from start to finish.

The timing depends on a few things. If we have the right part on our truck (which we usually do for common models), we can work more quickly. Sometimes your system is tucked away in a tight crawl space or attic, which naturally takes a bit longer to access safely.

Modern motors with all their computer components might need some additional programming or calibration steps, but even then, we’re talking about the same general timeframe. Our goal is always to get your comfort restored as quickly as possible while doing the job right the first time.

What is that burning smell coming from my vents?

A burning smell is never something to ignore, and we’re glad you’re asking about it! There are a few possibilities, ranging from minor to “call us right now.”

Sometimes it’s just dust burning off when you first fire up your heating system after months of not using it. This usually happens at the beginning of winter and creates a mild, brief burning smell that goes away quickly. It’s like that smell you get when you first turn on a space heater that’s been stored all summer.

More concerning is when the blower motor itself is overheating or having electrical problems. An overworked motor or a short in the wiring can burn the insulation, creating a sharp, acrid smell that doesn’t go away. This often means the motor is struggling and might need replacement soon.

Sometimes debris like leaves or pet hair gets into the blower assembly and burns when it hits the motor or heating elements. This creates a plastic or rubber burning smell.

Here’s when to take immediate action: If you smell a strong, persistent burning odor, especially if you see any smoke, turn off your system immediately at both the thermostat and the circuit breaker. Then call us right away. We’d rather come out and find it’s nothing serious than have you ignore a potential safety hazard.

Your safety is our top priority, and we’re always here to help when you need us most.

Trust the Experts for Your Furnace Needs

Your home’s blower motor might not be the flashiest part of your HVAC system, but it’s absolutely essential for your family’s comfort. Without it working properly, even the most expensive furnace or air conditioner becomes little more than an expensive paperweight. When you’re dealing with weak airflow, strange noises, or complete system failure, you need professionals who understand the complexity of modern HVAC systems.

Heater fan motor replacement isn’t something you want to tackle on a weekend afternoon. Today’s motors are sophisticated pieces of equipment, especially the newer ECM and CTM models that require precise installation and sometimes programming. One wrong wire or incorrect setting can damage your entire system, turning a moderate repair into a major expense.

At Henderson Heating & Cooling, we’ve been serving families throughout Southwest Missouri for years, including Lebanon, St. Robert, and Camdenton. Our technicians have seen it all – from simple capacitor failures to complete motor burnouts. We understand that when your heating or cooling stops working, you need reliable service fast.

We specialize in Daikin systems, which are known for their exceptional reliability and come with impressive 12-year warranties. But regardless of what brand you have in your home, our team has the expertise to diagnose the problem accurately and get your system running smoothly again. Our Comfort Promise means we stand behind our work, giving you peace of mind that the job will be done right the first time.

The longevity of your entire HVAC system often depends on how well your blower motor is maintained and, when necessary, properly replaced. Don’t let a failing motor damage other expensive components or leave your family uncomfortable during Missouri’s hot summers or cold winters.

When it’s time for a complete system upgrade, we’re here to help you steer your options and choose the right solution for your home’s specific needs. For more information about our comprehensive heating solutions, visit our furnace replacement services page.